Excellent quality PCB Thermal Camera analyzer

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for Excellent quality PCB Thermal Camera analyzer, Only for accomplish the good-quality product to meet customer’s demand, all of our products have been strictly inspected before shipment.

We have been experienced manufacturer. Wining the majority of your crucial certifications of its market for Factory Infrared Thermal Camera for PCB inspection thermal management thermal test temperature measurement, We always insist on the principle of “Quality and service are the life of the product”. Till now, our solutions have been exported to more than 20 countries under our strict quality control and high level service.

Instruction manual- CA pro software

Instruction manual- CA pro thermal analyzer

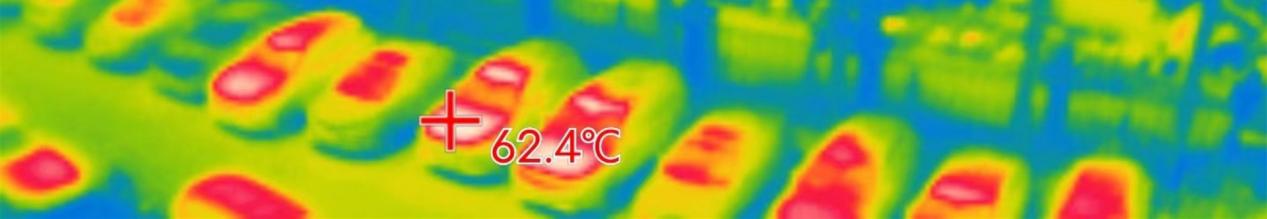

CA Pro Series Thermal camera Analyzer, upgraded from CA-10 with refined structure, advanced analysis software and higher sensor resolution,it’s able to detect and measure the data of object’s temperature changing with time based on the principle of infrared detection and imaging, store and analyze the reliability of the measurement results without time limit.

The CA pro mainly apply to the location, detection and maintenance of PCB leakage, short circuit and open circuit; evaluation and comparison of smart electronic devices; auxiliary analysis of electronic equipment performance; temperature control of electronic atomizer; temperature conduction analysis of heat conducting and radiating materials; uniformity analysis of materials; heating experiment, thermal simulation and verification of heating rationality in circuit design; thermal design, thermal management, etc.

Analysis mode

Circuit board analysis mode

Analysis mode of E-cigarette atomizer

Multi-dimensional analysis mode

Analysis mode of material thermal capacity

Defect analysis mode

Detection and analysis of heat conduction material

When the heat conduction material conducts heat, different color blocks can be set to view the distribution of heat conduction.

Analysis of the thermal design of the circuit board

When the circuit board chip heats up, users can check the components affected by the heat to adjust the layout.

Temperature control analysis of E-cigarette

Quickly tracking the heating rate and temperature of the atomizer

Thermal quality analysis of products and components

The aging degree of the tested components can be analyzed through the simultaneous comparison of the standard samples and the tested samples.

Material heat dissipation analysis

The heat dissipation of different heat dissipation materials can be analyzed through the temperature color block.

Circuit board pulse heating analysis

The thermal analyzer can quickly capture the occasional pulse heat emitted by some components on the circuit board due to failure.

Heating capacity analysis of heating materials at different voltages and currents

The heating rate, heating efficiency and heating temperature of materials such as heating wire and heating sheet at different voltages and currents can be quantitatively analyzed.

Analysis of the corresponding relationship between voltage, current and temperature

Location detection of short circuit and leakage

When repairing the circuit board, the leakage position can be located through the first, second and third high temperature points.

Fixed plate of atomizer test

Fixed atomizer resistance wire E-liquid injection test. Low resistance connector.

Automatic heating test bench for atomized electronic cigarettes

Automatic inhalation stimulation. Supporting the setting of pumping experiment times.

Experiment box

Simulating the temperature conditions of the equipment in a closed environment. Infrared thermal observation window with the diameter of 4cm. Built-in temperature sensor.

Power analyzer

Load voltage and current power analyzer, which can be connected to the analyzers from the specified manufacturers as required by customers.

Standard normal temperature reference

50℃ temperature reference for calibrating the accuracy of equipment temperature at normal temperature

Thermal camera can play a vital role in PCB inspections by detecting and identifying anomalies such as component overheating, connection errors and inadequate thermal management. Here are some key points to consider: Non-contact inspection: Thermal imaging cameras allow non-contact temperature measurement, meaning they can capture temperature data without physically touching the PCB or interrupting its operation. This is especially useful for inspecting sensitive electronic components. Thermal Anomaly Detection: Thermal imagers can identify hot spots on PCBs that may indicate a component is operating hotter than expected. This information helps identify potential issues such as insufficient cooling, poor thermal conductivity, or component failure. Quality Assurance: Thermal imaging cameras can be used during the manufacturing process to ensure that the PCB is constructed correctly and that all components are operating within acceptable temperature ranges. This can be done by examining the temperature distribution on the PCB and identifying any irregularities that might indicate a defect. Prevents failure and fire: Overheating or improper thermal management of components can lead to failure and, in some cases, fire. Thermal imaging cameras can detect these critical issues in real time so that timely action can be taken to prevent further damage or potential danger. Troubleshooting: When a PCB fails or exhibits unusual behavior, a thermal imager can be used as a troubleshooting tool to determine the root cause of the problem. By analyzing thermal patterns and temperature distributions, technicians can pinpoint problem areas and take appropriate corrective action. Faster Inspections: Using a thermal imaging camera, inspectors can quickly scan a PCB and quickly identify areas of concern. This saves time compared to traditional methods involving visual inspection or measuring specific points with temperature sensors. Documentation and Reporting: Thermal imaging cameras usually come with software that can record and analyze thermal images. This enables inspectors to document their findings, create reports and compare thermal data over time for trend analysis. Integration with other inspection methods: Thermal camera data can be combined with other inspection techniques such as X-ray imaging or optical inspection to provide a comprehensive assessment of the PCB. Integration allows for more detailed analysis and better understanding of potential issues. Automation and artificial intelligence integration: With advances in machine learning and artificial intelligence, thermal cameras can be used in conjunction with automated systems to more effectively analyze thermal data, detect anomalies, and trigger alerts or actions as needed.

| System parameters |

CA-20 |

CA-30 |

CA-60 |

| IR resolution |

260*200 |

384*288 |

640*512 |

| Spectral range |

8~14um |

||

| NETD |

70mK@25℃ |

50mK@25℃ |

|

| FOV |

42°x32° |

41.1°x30.8° |

45.7°x37.3° |

| Frame rate |

25Hz |

||

| Focus mode |

Manual focus |

||

| Working temperature |

-10℃~+55℃ |

||

| Measurement and analysis | |||

| Temperature range |

-10℃~450℃ |

-10℃~550℃ |

-10℃~550℃ |

| Temperature measurement method |

Maximum temperature, minimum temperature and average temperature |

||

| Temperature measurement accuracy |

±2 or ±2% for -10℃~120℃, and ±3% for 120℃~550℃ |

||

| Measuring distance |

3~150 cm |

4~200 cm |

4~200 cm |

| Temperature correction |

Manual/Automatic |

||

| Emissivity correction |

Adjustable within 0.1-1.0 |

||

| Data sampling frequency |

It can be configured flexibly, such as 20FPS, 10FPS, 5FPS, 1FPS. |

||

| Image file |

Full-temperature JPG thermogram (Radiometric-JPG) |

||

| Video file |

MP4 |

||

| Device dimension | |||

| Single board |

220mm x 172mm, height of 241mm |

||

| Double board |

346mm x 220mm, height of 341mm |

||

| Data acquisition accessories (not included in standard configuration) | |||

| Heating table |

Standard configuration of 2 oiling test holes of resistance heating wires, which can be customized |

||

|

Customized adjustment of the simulated suction degree, duration and times of the suction pump |

|||

| Data acquisition |

Recording of temperature data without time limit, including temperature change data, data corresponding to resistance heating wires and resistance values, data corresponding to simulated power supply time and temperature, and calculation of heating uniformity |

||

Study and research of new materials

Detection of short circuit and current leakage

Analysis of the heat dissipation rationality

Evaluation of the thermal conductivity and heat dissipation of materials

Analysis of temperature control of the atomizer heating of e-cigarette

Analysis of thermal effect of electronics components

Analysis of heating rate of heat sinks

Other applications: LED inspection, mould inspection, optical fiber welding, quality management…