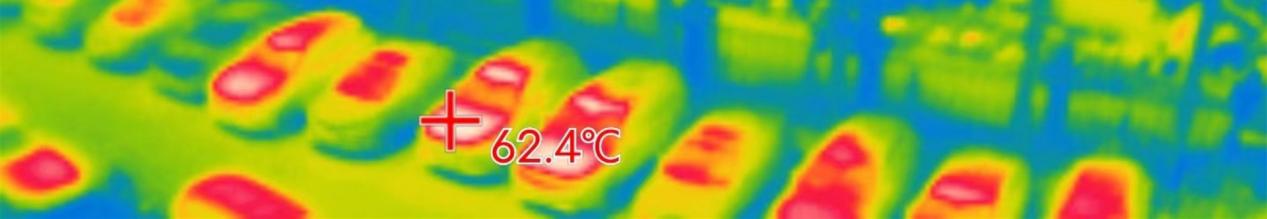

More and more infrared products are used in the thermal industry, steam pipes, hot air ducts, dust collector flues, coal silos in thermal power plants, boiler thermal insulation parts, coal conveyor belts, valves, transformers, booster stations, motor control centers, electrical The control is accurate and intuitive, and this non-contact temperature measurement method is more conducive for personnel to perform operations.

Other advantages of infrared thermal imaging detection:

Infrared thermal imaging cameras can also scan the heating network pipelines to accurately and quickly locate underground leaks, which is convenient for maintenance and can reduce energy consumption and ensure normal heating in winter.

High temperature objects in the environment have very little effect on the temperature measurement error of the infrared temperature measurement camera, and can even be ignored. Because the infrared temperature measurement thermal imaging camera is resistant to environmental factors, the influence of flying sand and dust on the measurement can also be ignored. Therefore, the temperature measurement is efficient and accurate.

When the burner needs to replace the fuel, the infrared thermal imaging equipment should be used to observe the flame size and the length of the fuel mixing zone, which can be recorded and saved as an endorsement for historical data analysis. The safety of coal storage and equipment safety are fully considered.

Post time: Mar-04-2021